|

Chris Shaw

Editor |

| Home> | INDUSTRIAL CLEANING | >High Pressure cleaning | >Hot or cold? You decide |

Hot or cold? You decide

04 July 2019

Sales of hot pressure washers are increasing steadily but are the benefits worthy of the higher investment? Sales director for Nilfisk John Brill investigates

Hot water pressure washers used to be a small percentage of total sales but across Europe sales have been increasing steadily over recent years. This may seem strange, given the price difference in the capital purchase cost, but look closely and common sense prevails.

Which cleans better?

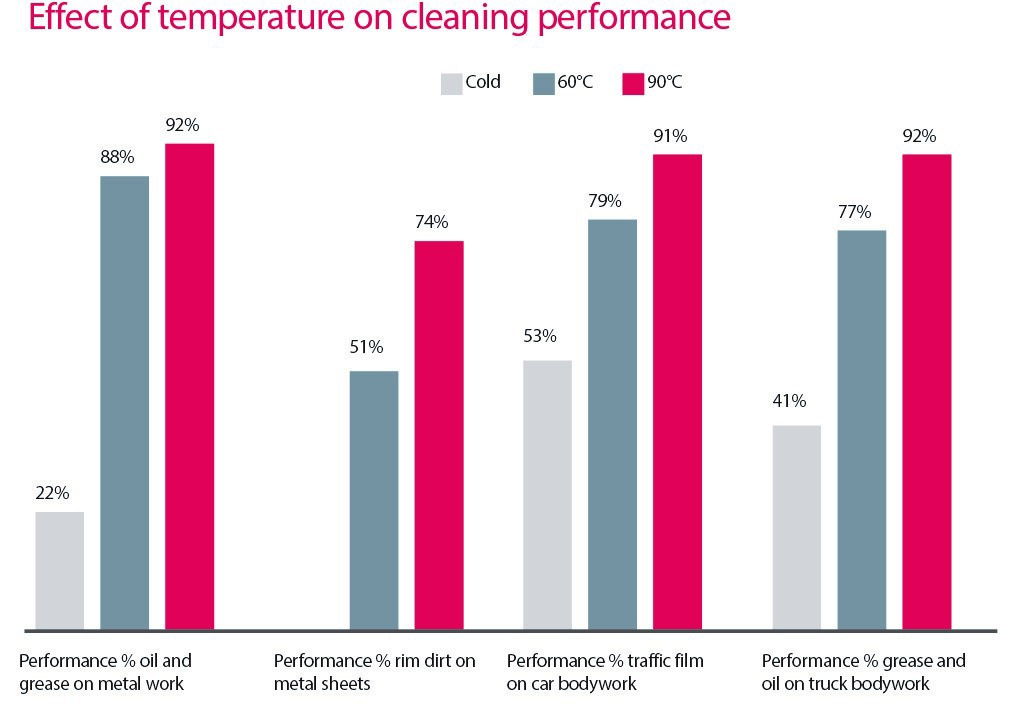

Independent tests have confirmed that hot water is much more efficient, reducing cleaning time and associated labour and water costs. The Wfk – Cleaning Technology Institute located in Germany – compared the cleaning efficiency of industrial pressure washers at different temperature levels for four applications. For all tests the bar pressure was set at 180 bar and the water flow rate at 810 litres per hour. All tests were conducted with water at cold, 60oC & 90oC degrees centigrade respectively.

The tests confirmed overwhelmingly that it is far more efficient to clean with water at 60oC whilst cleaning at 90oC results in disproportionate fuel costs which do not significantly impact the cleaning time.

Hot water will always do it better

Ignoring the issue of pressure and distance, hot water will always clean better because it is able to penetrate grease, oils and paint. Generally, a hot water pressure water is 50% more efficient than a cold-water option and has a faster drying time. The hotter the water the faster the result and the less water will be used in the process. Add pressure and you have superior power to break down and disperse unsightly dirt. Additionally, of course there is no abrasion or manual scrubbing which can potentially damage a surface.

At a time when pressure on costs has never been greater, and uncertainty about available labour remains high, it has never been more important to clean faster and use less water.

Safety of course must remain a priority, cleaning out tanks and containers with traditional methods can prove fatal but a high-pressure washer from a safe distance is ideal. Agricultural and construction equipment caked in dried on concrete, mud and excrement is so much easier to clean with water at the optimum 60oC which reduces fuel consumption.

Environmental concerns

In every sector customers are exerting pressure to reduce the amount of chemicals used. Pressure washing is an ideal solution for so many external cleaning requirements and using hot water often means that no chemicals are needed. Using water alone ensures that zero industrial chemicals are washed into waterways and there is no risk of any harmful residue.

Harsh chemical agents including Turpentine, white spirit, acetone and methylene chloride may be required in certain circumstances, including graffiti removal, but risks should be evaluated. Some facilities however now restrict the use of chemicals on site but chemical or no chemical, hot water will get the job done quicker and at a lower cost.

Modern boiler technology

Innovation across the industry has led to the development of improvements in boiler technology such as eco modes that heat water very economically to 60oC. The European Cleaning Machine Association (ECMA) rates and approves pressure washer boilers under their EUnited scheme.

Some EUnited approved boilers, including Nilfisk models, are classed as >92% efficient and therefore provide big reductions in fuel consumption. In some cases, saving up to 15% when compared to similar machines in their class.

Nilfisk’s range includes petrol and diesel versions that are lightweight despite having shock resistant aluminium frames. Ease of lift and transport is often crucial, so customers are advised to consider weight, size and manoeuvrability. The Nilfisk MC and MH range of industrial pressure washers can even be independent of normal water networks, having the ability to suck water from a tank, a pond or a river. Within this difficult sector a professional contractor needs all the help they can get. My advice is to see several machines in action and test the power of hot water for yourself.

- Nilfisk reveal autonomous cleaning machine program

- Scrubber drier scrubs out end user costs

- Micro scrubber success

- Nilfisk at The Cleaning Show

- Pressure washers improve productivity

- New CEO at Nilfisk

- Award for autonomous floor scrubber

- Steaming ahead with new range

- Focus on dealerships network

- Energy and water savings from Nilfisk