|

Chris Shaw

Editor |

| Home> | GENERAL EQUIPMENT & SERVICES | >Technology & Innovation?Services | >What is blow moulding? |

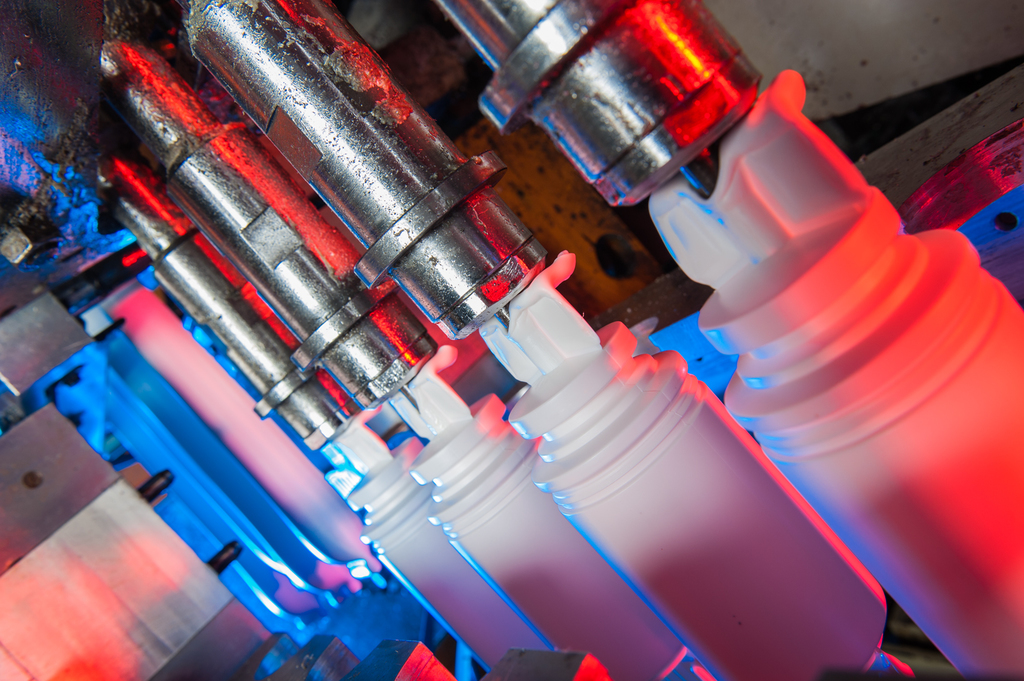

What is blow moulding?

27 June 2019

Blow moulding is a process to create quality plastic products for a wide and diverse range of industries. Coral Products (Mouldings) located in Haydock are specialists within this areas of plastic moulding and product design.

The blow moulding process is designed to manufacture high volume, one-piece hollow plastic products objects. If you require a large quantity of product/bottles/ tubs this is described as the ideal process to meet your needs.

Blow moulding can create uniform, thin-walled plastic containers economically. Costs in blow moulding are said to be lower compared to other processes. Additional benefits include: One-piece construction enabling full part creation instead of connecting parts; shapes in a wide variety can be created with this process; adaptability in product creating products that can be used for multi purpose.

A plastic tube is heated and filled with air until it essentially becomes a balloon of hot plastic called a “parison". A mould is then clamped around this, trapping the plastic while air continues to fill the parison into the shape of the tooling. This process is then repeated multiple times in succession.

With blow moulding, creating the mould is important but there are variables as well such as wall thinning, air leaks, flash, and streaks that must be monitored.

Examples of parts and products that are created using blow moulding include wet wipe tubs.

As a business Coral Products (Mouldings) excel within this field, creating quality tested products, within a circular economy business structure and innovative design incorporating recyclable materials.

To find out more please email national account manager Steve Winstanley: [email protected]

- No related articles listed